Environmental test chambers play a pivotal role in ensuring the durability and reliability of products across various industries. By artificially replicating extreme environmental conditions, these chambers provide valuable insights into how products will perform in real-world situations. This detailed exploration will dive into the mechanisms of environmental test chambers, unraveling how they operate, their diverse applications, and the technological advancements driving their evolution.

Understanding Environmental Test Chambers

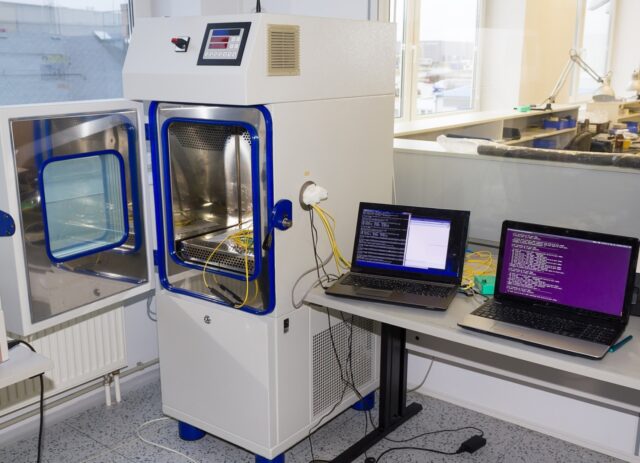

At its core, the environmental test chamber is a sophisticated system designed to create highly controlled environments. Their primary purpose is to test the effects of different environmental conditions on products, materials, and components. By simulating conditions like extreme temperatures, varying humidity levels, and even specific atmospheric pressures, these chambers allow researchers and manufacturers to observe how products behave under stress. The goal is to identify potential weaknesses or failures before the products are marketed or used in critical applications.

Mechanisms of Temperature and Humidity Control

Central to the functionality of environmental test chambers is their ability to accurately control temperature and humidity. These chambers are equipped with heating and cooling systems that can create a wide range of temperatures, from the intensely cold to the extremely hot. Heating elements, often resistance heaters, are used to generate high temperatures, while cooling is typically achieved through refrigeration systems, including advanced cascade refrigeration for extremely low temperatures. Humidity is controlled through a combination of humidifiers, which add moisture to the chamber, and dehumidifiers, which remove it. The precise regulation of these conditions is critical, as it ensures the reliability of the test results.

Advanced Control and Monitoring Systems

Modern environmental test chambers are integrated with advanced control systems. These systems allow users to program specific environmental conditions and sequences, replicating the various stresses a product might face over its lifespan. High-tech sensors continuously monitor the conditions within the chamber, ensuring that the parameters remain within the set limits. These systems are often capable of logging data, providing a detailed record of the test conditions, which is crucial for analysis and certification processes.

Diversity in Design and Application

The design and size of environmental test chambers vary significantly based on their intended use. From compact benchtop models used in small laboratories to large walk-in chambers capable of accommodating sizeable components like vehicle parts or even entire vehicles, the variety is vast. This diversity extends to their applications. In the aerospace industry, for instance, components must withstand extreme environmental conditions, and these chambers simulate those stresses. The automotive industry relies on them to test vehicle components for endurance in various climates. Similarly, in the pharmaceutical, electronics, and consumer goods sectors, environmental test chambers are indispensable tools for quality assurance and safety testing.

Ensuring Precision and Reliability

The effectiveness of an environmental test chamber hinges on its precision and reliability. Regular maintenance and calibration are essential to ensure that the chamber performs accurately. Sensors, which are critical for monitoring conditions, must be checked and recalibrated regularly to maintain their precision. This rigorous upkeep is necessary not only for the accuracy of test results but also for compliance with various industry standards and regulations.

Overcoming Challenges and Embracing Innovation

Despite their effectiveness, environmental test chambers face challenges such as high energy consumption and the need for continuous technological improvement. Manufacturers are constantly innovating to enhance the efficiency, accuracy, and capabilities of these chambers. This includes developing more energy-efficient models, integrating advanced control systems for more precise simulations, and expanding the range of environmental conditions that can be simulated.

Enhancing Realism in Environmental Simulation

One of the key areas of focus in the development of environmental test chambers is the enhancement of realism in environmental simulations. As products become more sophisticated, so too must the testing environments that evaluate their endurance and reliability. Future environmental chambers are expected to simulate a broader range of conditions, including rapid weather changes, high-altitude pressures, or even the corrosive atmospheres found in certain industrial environments. This level of realism ensures that products are not only durable under standard conditions but also resilient in the face of unexpected or extreme environmental changes.

Integration with Emerging Technologies

The integration of emerging technologies is another significant trend in the advancement of environmental test chambers. Technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning are beginning to play a role in the operation of these chambers. With IoT, for example, environmental test chambers can be remotely monitored and controlled, increasing efficiency and flexibility in testing procedures. AI and machine learning algorithms can analyze the vast amounts of data generated during tests, uncovering insights that might be missed by human analysis and predicting potential failures before they occur.

Addressing Environmental and Energy Concerns

Environmental sustainability and energy efficiency are increasingly important in the design and operation of test chambers. Manufacturers are working on solutions to reduce the carbon footprint of these devices. This includes the use of eco-friendly refrigerants, better insulation materials to reduce energy loss, and software that optimizes the chamber’s operation for energy efficiency. As global awareness of environmental issues grows, the push for greener technologies in all sectors, including testing and quality assurance, becomes more pronounced.

Customization for Specific Industry Needs

The customization of environmental test chambers to meet specific industry needs is another area of development. Different industries have unique requirements for environmental testing. For instance, the pharmaceutical industry requires highly precise humidity control for stability testing, while the automotive industry might focus more on temperature extremes and rate of change. Manufacturers of these chambers are increasingly offering bespoke solutions that cater to these specialized requirements, ensuring that the testing process is as relevant and effective as possible.

The Role of Environmental Chambers in Product Development

Environmental test chambers are not just tools for quality control; they are integral to the product development process. By testing products in extreme conditions early in the development cycle, manufacturers can identify and address potential issues, leading to a more robust and reliable product. This proactive approach to testing helps in reducing costly recalls and enhances consumer trust in the product.

Conclusion

In conclusion, environmental test chambers are essential in ensuring the safety, reliability, and durability of products across a multitude of industries. As technology advances, these chambers are becoming more sophisticated, capable of simulating a wider range of environmental conditions and providing more accurate and reliable data.