Technology has been changing our lives segment by segment. While it has been an important part of manufacturing for decades, the rise of 3D printing has revolutionized the industry. Additive manufacturing – building objects by printing layers over layers – has come a long way from design and prototyping to scalable production.

This means that the production of almost everything you can imagine – from car parts to food – can be completely democratized. Manufacturing using 3D printing technology is more precise, faster, and cheaper. 3D printing machines have already made their impact on many businesses, but they’re also making their way into homes, disaster sites, and eventually – probably outer space. Yes, aeronautics can prosper from this technology the same way healthcare can.

So let’s take a look at how this powerful technology will shape the future of manufacturing.

Research & Experimentation

Before we dive into the revolution at hand, let’s see how we got here. When it first appeared, 3D printing technology had limited capabilities and slow speed, so its most common use was in prototyping. The evolution into a cost-effective and sustainable technology capable of manufacturing physical goods didn’t happen overnight. It took many years of research and experimentation which brought breakthroughs such as light rays.

The advancements of the 3D printing technology gave birth to new & improved 3D printing machines, which immensely increased printing speed. Additionally, these new 3D printers came with different filament options available widening the array of materials and therefore increasing their value and use in diverse applications.

These factors are the crucial ones that launched the 3D printing industry on the road of innovation and creative application. Now that the competition and investments are growing, let’s see what kind of revolution awaits us in the manufacturing industry.

1. Rational Use of SUSTAINABLE materials

Sustainability is one of the most important issues today, and the 3D printing industry has an opportunity to be sustainable from day one. Firstly, the far more rational and considered use of materials, leading to a great reduction of waste and scrap, makes sustainability one of the most appealing aspects of this new technology.

Secondly, 3D printing reduces the ecological footprint that comes from transportation. With the digital and distributed manufacturing for both mass-volume and highly customized production, the need for the transportation of materials and parts is almost completely eliminated.

And thirdly, it deals with the biggest issue in the additive manufacturing industry – the fact that only a small portion of materials was recyclable or reusable. According to Ink Station, many of the 3D printer filament types are biodegradable and renewable, which can lead to a wide array of products composed of entirely bio-based resources.

2. Minutes Instead of Days

As we’ve said at the beginning, the speed of 3D printing was a big concern for decades. But with the new emerging technologies came a great increase in speed compared to traditional printers, and modern ones today can print a centimeter per minute. This means that days of work are now turned into minutes, so it’s obvious we’re talking about a phenomenal speed increase. The reduction of time for the whole process – from design, across prototyping, to actual manufacturing/printing – is more than dramatic.

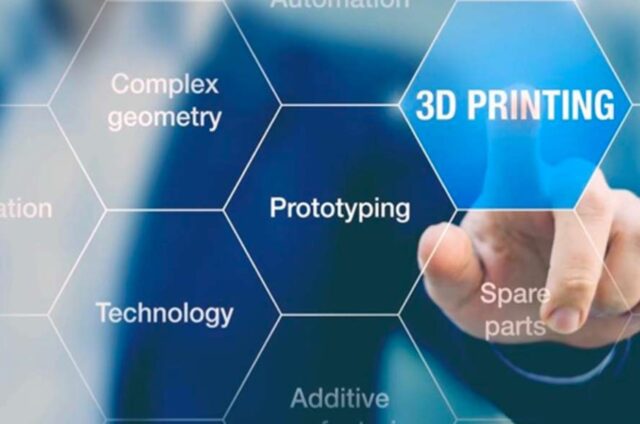

3. More Sophisticated Application

With the immensely increased speed, the long-known geometric accuracy of 3D printing truly came to shine. Many complex tasks that were almost impossible to accomplish using traditional design and manufacturing methods can now be easily achieved with great results. In fields where precision and minute details are extremely important, such as mechatronics industries, automobile technology, aerospace technology, etc., the newer and more sophisticated application of 3D printing opens a whole new world of manufacturing possibilities.

Additionally, both the quality and performance of 3D printing have also increased. Combined with the number of metal alloys that can be printed, it’s just a matter of time when 3D printing is going to take over the field of direct metal printing completely.

4. Accuracy & Precision

Another field where accuracy and precision are crucial – literally a matter of life and death – is the medical industry. 3D printing is already put to use for creating a variety of surgical and medical tools, hearing aids, dental fixtures and implants, etc. Not only can all these devices be created easily and with great precision, but also in a cost-effective way. Accordingly, the costs of treatments for patients will also be reduced.

3D printing technology will also boost the precision and expertise of the surgeons involved. Printing of lifelike 3D surgical models allows them to practice more complex procedures like cardiovascular operations, which will reduce surgery time by up to 30%.

And all this is just scratching the surface. The immense possibilities which 3D printing opens in the healthcare industry are clear from the fact that we’ve never been closer to the creation of an artificial heart.

5. Food & Shelter

Maybe some of you frowned upon the mention of manufacturing food at the beginning, but the truth is that many people see 3D printing as a way of ending hunger. 3D printers have the power to enable everyone to feed themselves with fully nutritious meals, with all nutrients synthesized in layers. In the not so distant future people will be able to buy oils and powders at their local grocery stores and fill up their printing cartridges. These will also be made of sustainable materials such as insect protein, they’ll be long-lasting, and easy to transport.

Similarly, 3D printing can also put a stop to homelessness, as it’s already making a revolution in easy-to-print home construction, making it more efficient and cheaper at the same time.

6. Road to Innovation

If everything mentioned by now is not enough for a revolution (and it is), 3D printing is paving the way to even greater innovation. We all know that startups are at the heart of every innovation, while larger companies usually play it safe. Until recently, the manufacture of a given product had very high initial costs which made startups refrain from investments in large-scale manufacturing of their innovative products, due to their limited resources and budget.

But today 3D printing is changing all that. It has made the design, prototyping, and actual production much cheaper, allowing innovative startups to manufacture on a large-scale without the need to raise a huge amount of initial investment capital.

Moulding the Future

Take all the above-mentioned advantages of 3D printing – speed, cost, accuracy, a huge variety of sustainable materials – and then combine them with other emerging advanced technologies such as robotics, IoT, cloud technology, etc. It’s clear that 3D printing has established itself as a powerful catalyst that will mould the future of manufacturing.

It is not a question of whether or not 3D printing can revolutionize manufacturing. It took decades to come to its true potential, but the revolution is now here. And with each passing day, more innovations of its use are paving the way forward towards a more prosperous and egalitarian world.